What Is A Shaft Coupling?

An EF shaft coupling bearing (ลูกปืนจับยึดปลายเพลา EF, which is the term in Thai) is a tool used to connect two shafts to transmit power. A shaft connects two machines and absorbs and transmits torque and rotational movements. This device is essential as it ensures the machines’ minimum damage and wear and tear.

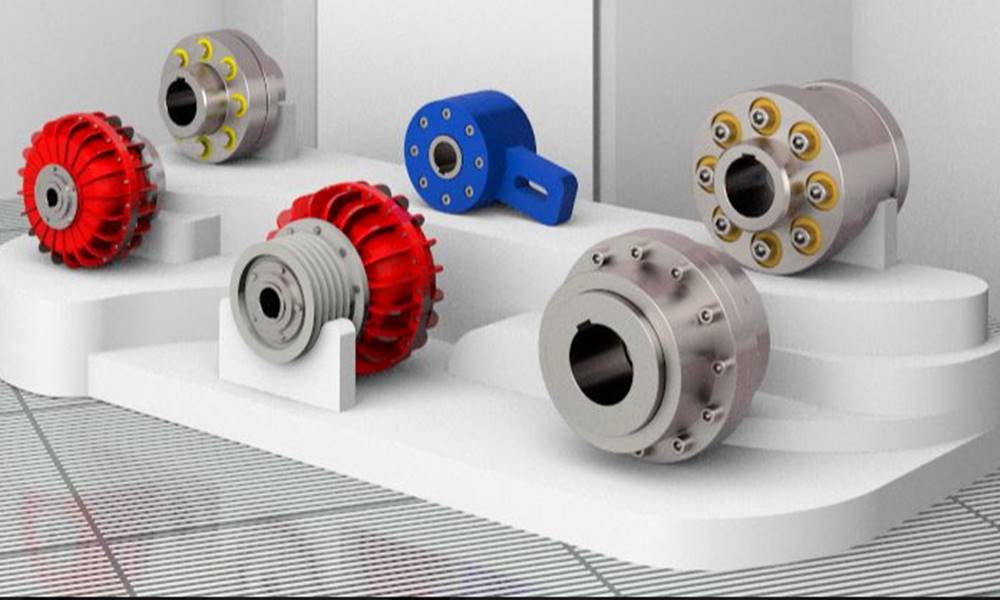

Types Of Shaft Couplings

Shaft couplings come in various types to cater to the needs of different machines. Examples of various shaft couplings are as follows:

- Flexible Couplings: This type of shaft coupling has the flexibility required for absorbing shock emitted from machines.

- Rigid Couplings: Rigid couplings ensure a strong connection between two machines. This type of coupling is used in machines where precise alignment is required.

- Fluid Couplings: Fluid couplings work on hydraulic principles. This ensures that the torque is transferred smoothly.

- Universal Joints: This type of coupling is used where non-linear motion transmission is required.

Purpose Of A Shaft Coupling

A shaft coupling bearing tool is deployed to connect two machinery parts. It also serves the purpose of torque and rotational movements between two machines. A shaft coupling ensures no misalignment, angular offset, or displacement while operating machinery. Shaft coupling offers the benefit of power transfer while providing minimum wear and tear for the machinery involved.

Benefits Of Using A Shaft Coupling

Apart from ensuring machinery safety, a shaft coupling has various other benefits.

- Torque Transmission: Shaft coupling ensures torque transfer from one shaft to another. This results in the efficient operation of the machinery involved.

- Alignment: Shaft Coupling ensures proper alignment between the shafts of two different machinery. This, in turn, ensures that the types of machinery are safe and secure while in use.

- Vibration Dampening: A coupling shaft between two types of machinery ensures that the coupling shafts dampen the vibrations emitted from the machine parts.

- Protection From Overload: A coupling shaft protects the machinery from sudden shock and overload of all types. This protects the machinery from damage and regular wear and tear.

- Flexibility: Shaft couplings ensure that there is maintenance of the machine components. This further provides less time and money spent on repairs and replacements.

- Efficiency: Coupling shafts enhance the efficiency of the machinery by transmitting power to various parts of the machinery. This improves energy efficiency by reducing losses from poorly aligned shafts.

- Versatility: Since there are different types of shaft couplings for every machinery needs. This ensures a proper kind of coupling shaft for every industrial setup.

Conclusion

A shaft coupling bearing tool is one of the most critical tools in a machine as it ensures the safety of the machinery. It also ensures that the machinery stays in prime shape while being in use. There are various types of coupling shafts to choose from to fit the needs of the machinery.

Comments